Sealing solutions for hydropower plants

Freudenberg Sealing Technologies is a leading provider of high-performance materials and advanced products. In researching, developing, and introducing innovative product and process solutions, we draw on 175 years of engineering and materials expertise. Throughout, the technological desires and requirements of our customers have always been and continue to be at the forefront. The portfolio includes seals and plastic molded parts such as O-rings, rubber molded parts, rubber-metal composites, foam molded parts, semi-finished products, and machines for precision seal machining.

Renewable Energy

Choosing the right mix of renewable technologies to invest in is the key to true sustainability. Hydropower is one of the oldest sources of energy. Over more than two millennia, a mature technology has been developed that produces the second largest share of renewable energy worldwide after the traditional use of biomass. About half of the world’s Hydro Power energy production is generated in run-of-river power plants, the other half in storage power plants.

Key Components

For every power plant, seals and corresponding guides and sliding bushings are key constituents. The sealing experience of more than two decades in the field of hydro power distinguishes Freudenberg Sealing Technologies as a developer and manufacturer of sealing and guiding solutions. Old leatheror fabric-reinforced seals can be replaced by machined seals with the appropriate material pairing to suit the medium. Reliable and durable compounds have already been developed for very abrasive media such as glacier water etc.

Sealing and guiding solutions

- Hydraulic pneumatic seals (piston-/rod seals)

- Static seals

- Rotary seals

- Gaskets

- High pressure seals

- Large seals

- Miniature seals

- Special seals

- Guiding elements

- Back-up elements

- Wiper elements

Materials

- HPU: premium, taiga, lubric

XHPU: solid, lubric - NBR: standard, solid, taiga

- EPDM: spring, diet

- NR, SBR

- PTFE: carbon, graphite, MoS2, nature

- POM, PA, PE-UHMW

- Guide belts, rings and plates: (HGW, graphite/PTFE und PTFE-carbon)

- Flat gasket materials in various designs

Standards

- The products comply with the ISO standards ISO 9001, ISO 14001.

Applications

Seals and bearings for a variety of applications, e.g. shut-off devices, deflectors, trunnions and pump bearings, ring piston valves, vane seals, nozzle inlet, oil and/or water hydraulics, etc.

Types of hydropower plants

Low pressure power plants

Use for the base load

Turbine types

- Kaplan turbine

Types

- River power plants

- Tidal power plants

- Wave power plants

Medium pressure power plants

Use for base load/medium load

Turbine types

- Francis turbine

Types

- River power plants

- Storage power plants

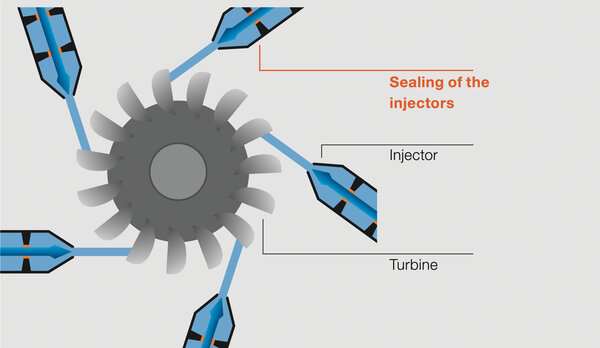

High pressure power plants

Use for peak load

Turbine types

- Francis turbine

- Pelton turbine

Types

- Storage power plants

- Pumped storage power plants

- Cavern power plants

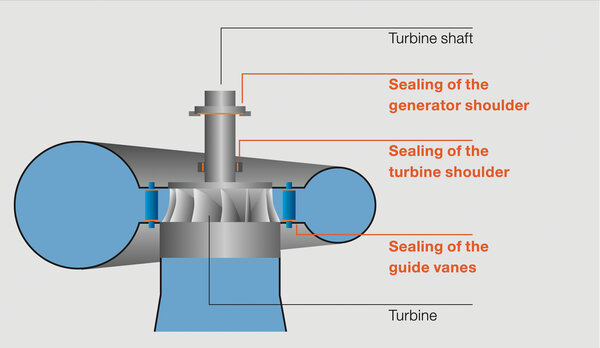

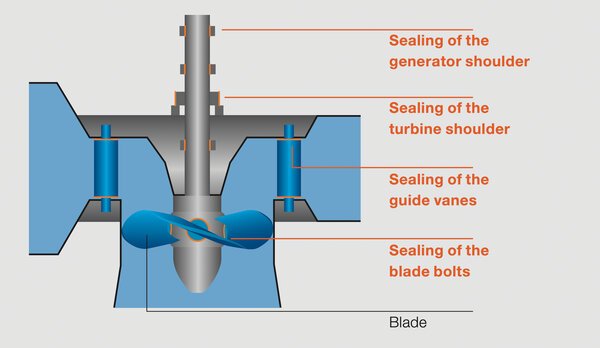

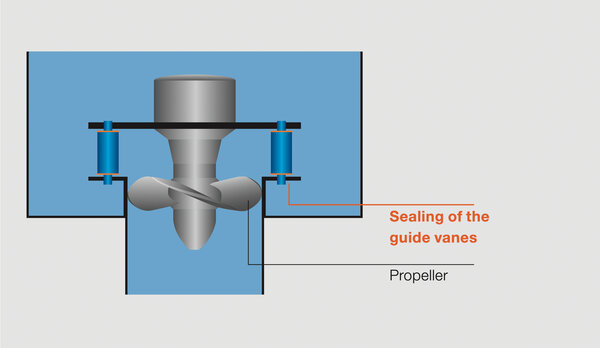

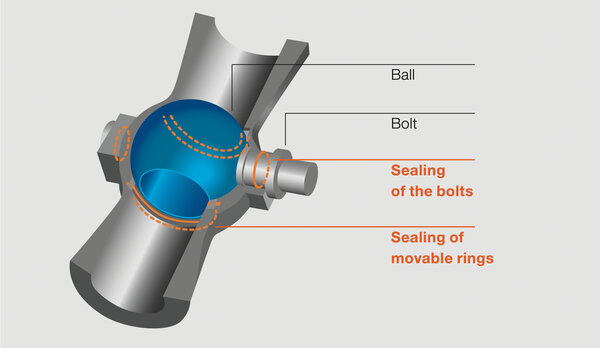

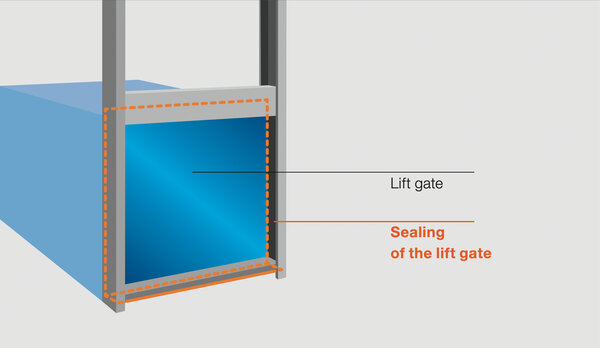

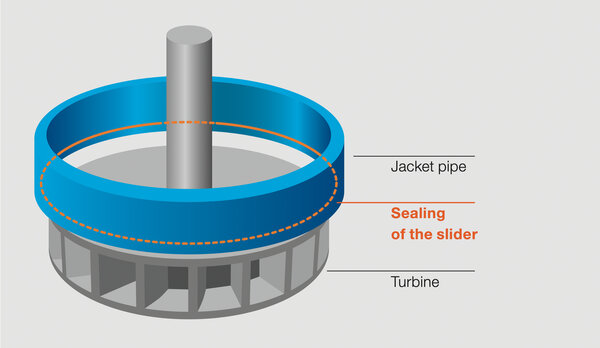

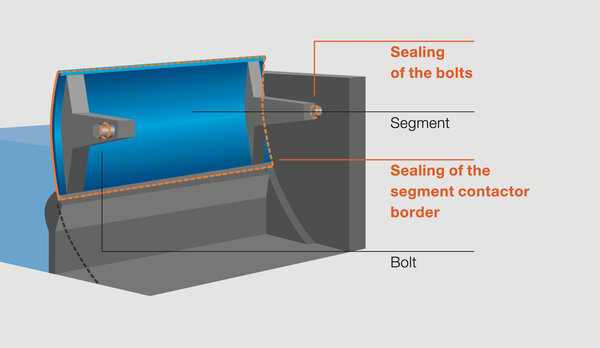

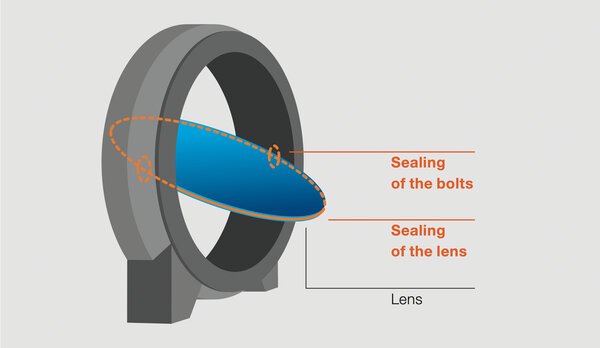

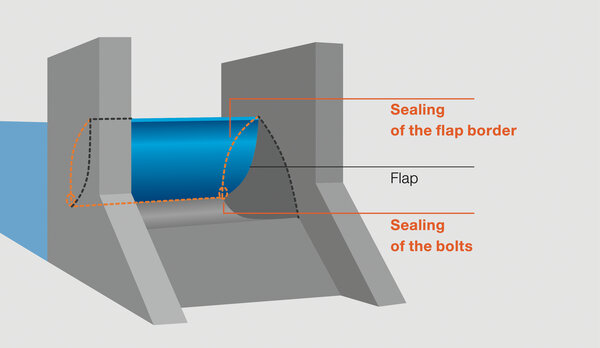

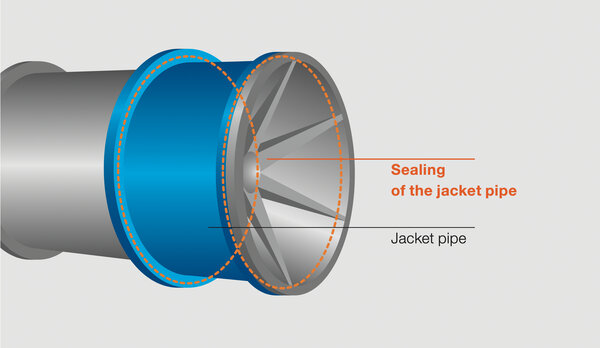

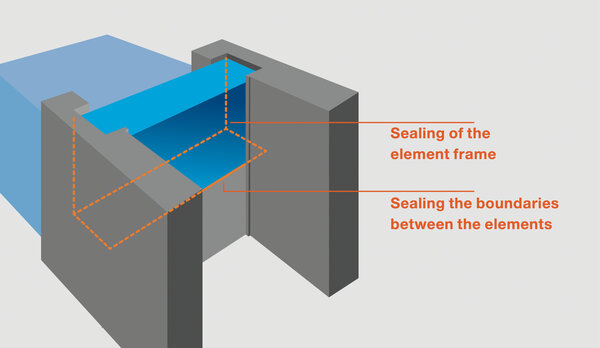

Sealing solutions application examples

Sealing elements

Customer-specific sealing solutions with suitable sealing geometry and sealing materials for the following applications.

- Rod and piston seals

- Dirt wiper

- Rotary seals

- Backup rings

- Guide rings

- customized special seals/profiles

In our brochure "Seals – Profile, Application and Material Overview" you will find further solutions for seals and in our brochure "Seal Materials" you will find a variety of suitable materials for the hydro power sector. We also offer other materials on request.

Properties of our sealing elements

- Sealing profile according to the application

- Any change of dimensions is possible (machined gaskets)

- Adjustment of the gasket prestress

- Abrasion-resistant sealing materials even with glacier water

- Sustainable solutions for the replacement of roof cuff sets

Guide elements

HGW is a technical composite material made of synthetic fibres and thermosetting resins. All HGW types are available with integrated solid lubricant.

Due to its physical and mechanical properties, HGW is a bearing material that can absorb very high transverse loads. By using different formulations and the appropriate lubricant additive, the physical and chemical properties of the material can be adapted to suit a wide range of applications.

The use of HGW is particularly recommended when high transverse loads (up to 110 N dynamic) are present.

Applications

- Bearing bushes

- Guide rings (turned version)

- Guiding belts

- Sliding plates

Features of our guide elements

- Natural low coefficient of friction

- Almost any liquid can be used as a lubricant

- Hard-wearing

- Excellent bearing material

- Low moisture absorption

- Can be easily manufactured to the exact specifications of the customers

- Exceptional dimensional stability, even in wet conditions

Service and support

On-site assessment, development of the new Sealing up to assembly support on site

The most important parameters of the seal can already be defined in the first meeting. In cooperation with the power plant operator, the appropriate sealing profiles and material properties are calculated so that they are suitable for the required application.

Seals up to ø550 mm are manufactured in our company. This allows for a very short delivery date with optimal planning. Seals that are larger can be delivered within a few days.

Training on site – is one of our helpful options

O-rings are glued on site in the form of an O-ring for a secure seal.

For this purpose, we offer training for your personnel on the correct handling of cleaning and preparation of the glued joint (to make optimal use of the glue together with the cutting and gluing gauge).

Manufacturing process

Endlessly machined seals up to 2.5 m diameter

We offer more than 140 individual hydraulic, pneumatic and special sealing profiles, which are produced by our machine which use the latest CNC lathes.

We can produce each profile from a batch size of 1 piece and from an inner diameter of 1 mm, in any size, shape and measurement in a variety of high quality sealing materials.

Welded versions over 2.5 m diameter

For larger diameters or inaccessible areas HPU materials are also welded. The mechanical properties are almost identical to those of endless seals.

The vulcanization process

We use state-of-the-art CNC-controlled presses to pro- duce high-quality rubber moulded parts, membranes and seals. We manufacture the necessary mould tools and aids for processing standard and special profiles in our own tool shop. The parts are mainly used for Kaplan and bulb turbines as well as gates and flaps.

Advantages

- Endless profiles or segments are possible

- Round as well as square seals are possible

- Suitable for dynamic applications

Glued solution for inaccessible areas

The bonding process has changed the development of sealing (mainly used for round cord seals). To connect the two ends our mobile cutting and gluing set is helpful.

Advantages

- Only primer and glue and a sealing set used

- Uniform property over the entire circumference the seal

- Suitable for static applications

We …

- are a sealing and plastic parts manufacturer

- see ourselves as a partner to our customers

- are independent, holistic and solution-oriented

- are an international network company and we work world-wide

- see our company culture like life: varied, complex and exciting

- value greatly the individuality and the expertise of the staff

- are committed to high professional ethics and integrity in all we do

All this creates a passionate, innovative and dynamic team to support your business.

Want to learn more?

Visit our Freudenberg Sealing Technologies website